How analytical insights help craft fine Languedoc wine

By Michael Hubanddb discovers how FOSS Analytical equipment has helped Gérard Bertrand to maintain high quality in its award-winning wines.

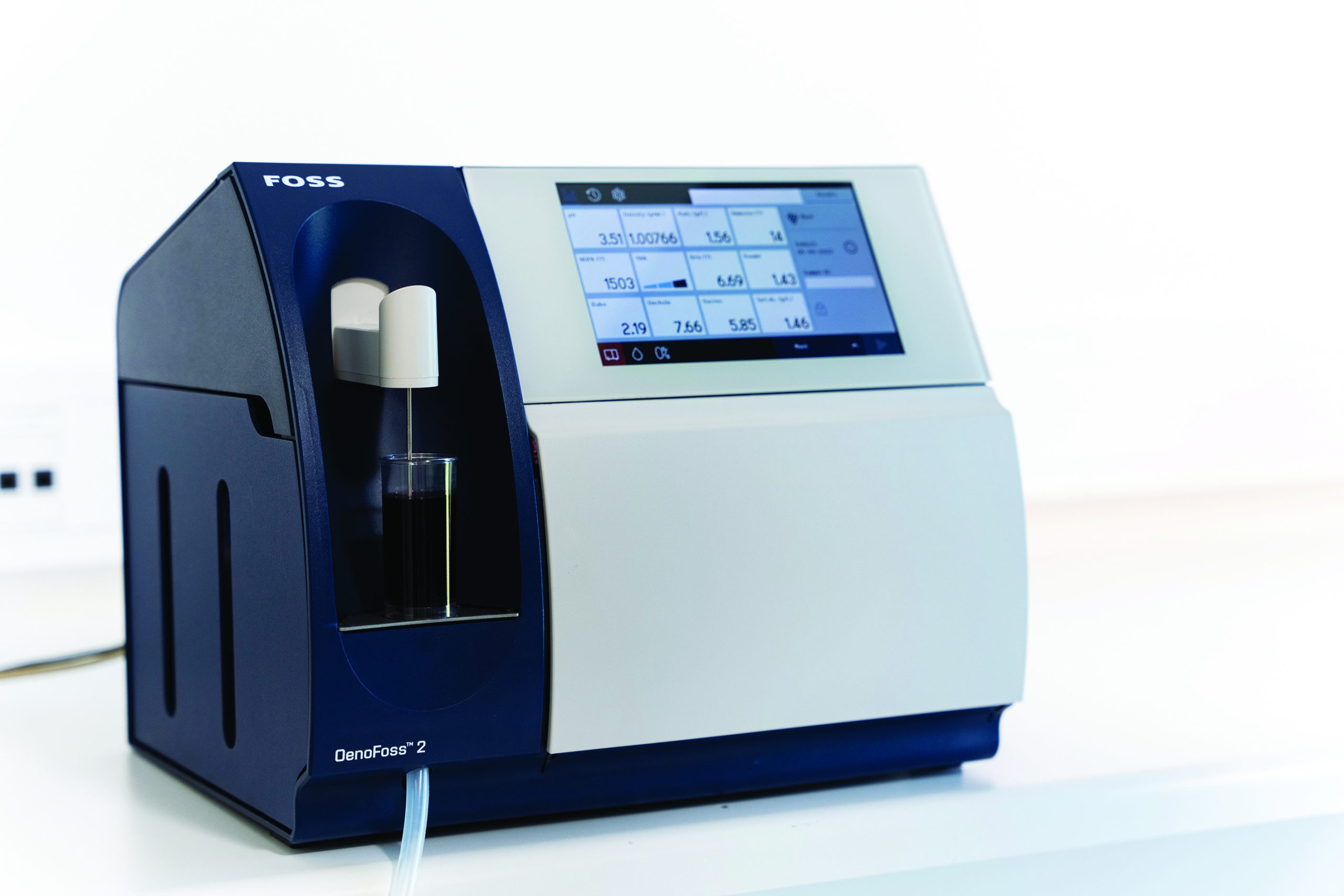

Putting aside the oft-referenced factors of unique terroir, prestigious grape varieties or generations of experience, how does one make fine wine? The solution, increasingly, is small tabletop equipment that looks more at home in a laboratory than an ancient cellar. For the last 25 years, FOSS Analytics has been producing such technology and helping winemakers get the best from their grapes.

Though the technology is complex, the premise is simple. By checking the chemical makeup of the wine-to-be, whether must, fermenting juice or a wine ready for bottling, winemakers can act quickly and precisely to make the best possible product. Using a FOSS machine, one can measure up to 30 parameters from a single sample, including sugar, acid, nitrogen and sulfur dioxide levels, as well as tannin ripeness.

For fine winemakers, where precision is key, the technology is often indispensable. Gérard Bertrand Group understands that better than most. It has been using FOSS machines to support in crafting its award-winning wines, which have taken home major international prizes, helped put the Languedoc on the map for fine wine and secured Gérard Bertrand a place in The Master Winemaker 100.

Paul Correia, quality and CSR manager at Gérard Bertrand, spoke to db about how such rapid analytical machines aid the producer’s winemaking.

These sorts of analytical instruments (ones that deliver multi-parameter results in a few seconds) came on the scene about 25 years ago. When did you start using such an instrument and why?

We started using this practice in 2004. Very quickly, the tool’s reliability and efficiency pleased us. It saves time as a single instrument can provide us with a range of essential parameters to meet our high standards for producing excellent wines.

What were you doing for your wine analytics before adopting such a machine?

We used manual methods and/or enzymatic methods.

How has rapid analysis changed your winemaking?

This facilitated the analysis steps, which was very advantageous for us given the level of precision and detail we apply to our winemaking processes. It is a greatly appreciated time and efficiency gain, thanks to the fact that all parameters are analysed in a single machine. This solution for performing a complete analysis very quickly has revolutionised our way of working and has allowed us to gain autonomy in our analyses.

How does having a rapid analysis machine help you in crafting your fine and award-winning wines specifically?

The results are precise and reproducible, helping maintain consistent wine quality. It also enhances our responsiveness in verifying regulatory compliance during blending and throughout the winemaking process.

How do these machines change your day-to-day routines?

They have become indispensable tools that improve and contribute to the enhancement of the winemaking process.

How did you decide such a machine was worth the investment?

If there is one thing we never compromise on, it is the quality of our wines and the attention we give both in the vineyard and in the cellar. The technological choice was never debated and is still not debated today.

We quickly invested in technology because very early on, we knew that these tools would offer many operational advantages and would allow us to gain efficiency and achieve the level of excellence and rigour in winemaking that we are looking for. And indeed, we always consider the investment in technology to be worth it as long as it benefits the quality of our wines.

What ‘dream feature’ would you pick for a future analytical instrument?

We still need complementary devices to perform certain controls (oxygen, protein stability, cold stability, colour) because methods do not exist in FTIR to perform these controls, or they are not robust enough to apply our control plans. The all-in-one device is a dream. But is it desirable if it comes at the expense of reliability?

Related news

Should Rioja increase its focus on white wine?

The 'family spirit' behind Champagne Gardet's 130th anniversary