Crealis reduces carbon emissions on sparkling foils material

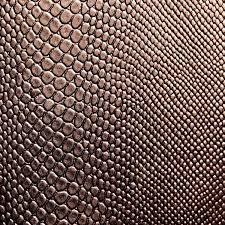

Capsule and closures firm Crealis Group has reduced the carbon emissions of its Enoplastic brand’s Derma75 product, delivering a more sustainable material for sparkling foils.

The new Derma75L is a sustainable evolution of the material used for foils. It is an eco-friendly product which is a green alternative to the commonly used polylaminate, and which the company produces 1800 tonnes of a year for a total of 600 million finished products — each of which dresses a bottle of sparkling wine.

The new and more performant aluminium alloy reduces the carbon emissions by 17% compared to the former version, based on an independent Life Cycle Assessment of 2023 data. But the company claims it still ensures the same performances of the finished product as the previous, more carbon intensive version.

Founded in 1957 in Bodio Lomnago, Italy, Enoplastic is one of the global leaders in the production of closure solutions for the wine and spirits industry, producing heat shrink and polylaminate capsules, sparkling foils, screw cap, wirehoods and technical corks.

Its sustainability philosophy, which has already been adopted for the launch of PET+ — produced with 35% of recycled plastic at the same price of the previous version with 20% of recycled plastic — is part of the ESG strategy of the group.

Partner Content

Recently it has committed to set short-term corporate reduction targets based on the Science Based Targets Initiative (SBTi), reducing emissions by 42% for the direct greenhouse gas emissions, and the indirect emissions related to energy consumption, and by 25% for the indirect emissions from activities within the supply chain. The targets are pending approval related to 2022 data and to be realised by 2030, it said.

Within the first quarter, Crealis has also brought to full capacity the operation of its new solvent recovery plant at the Enoplastic site, which will allow the Bodio Lomnago production site to work without purchasing any solvents.

Davide Pagano, Crealis S.p.A. general manager said: “We are investing to ensure increasingly sustainable and qualitative materials maintaining final prices unchanged: a free of charge “upgrade” for our customers, absorbing all the additional costs in terms of production process and raw materials.

“A responsible choice toward the market that demonstrates how much we believe in the innovation value for a tangible breakthrough in the sign of sustainability, but also in the circularity of the process: any improvement on the top of the production scale has its consequences on the whole supply chain, contributing to reaching partner’s goals as well.

“Basically, a win-win solution toward economies of scale that will make sustainability more and more accessible even from an economical point of view.”

Related news