This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

How using 3D printing reduces costs and helps to save the planet

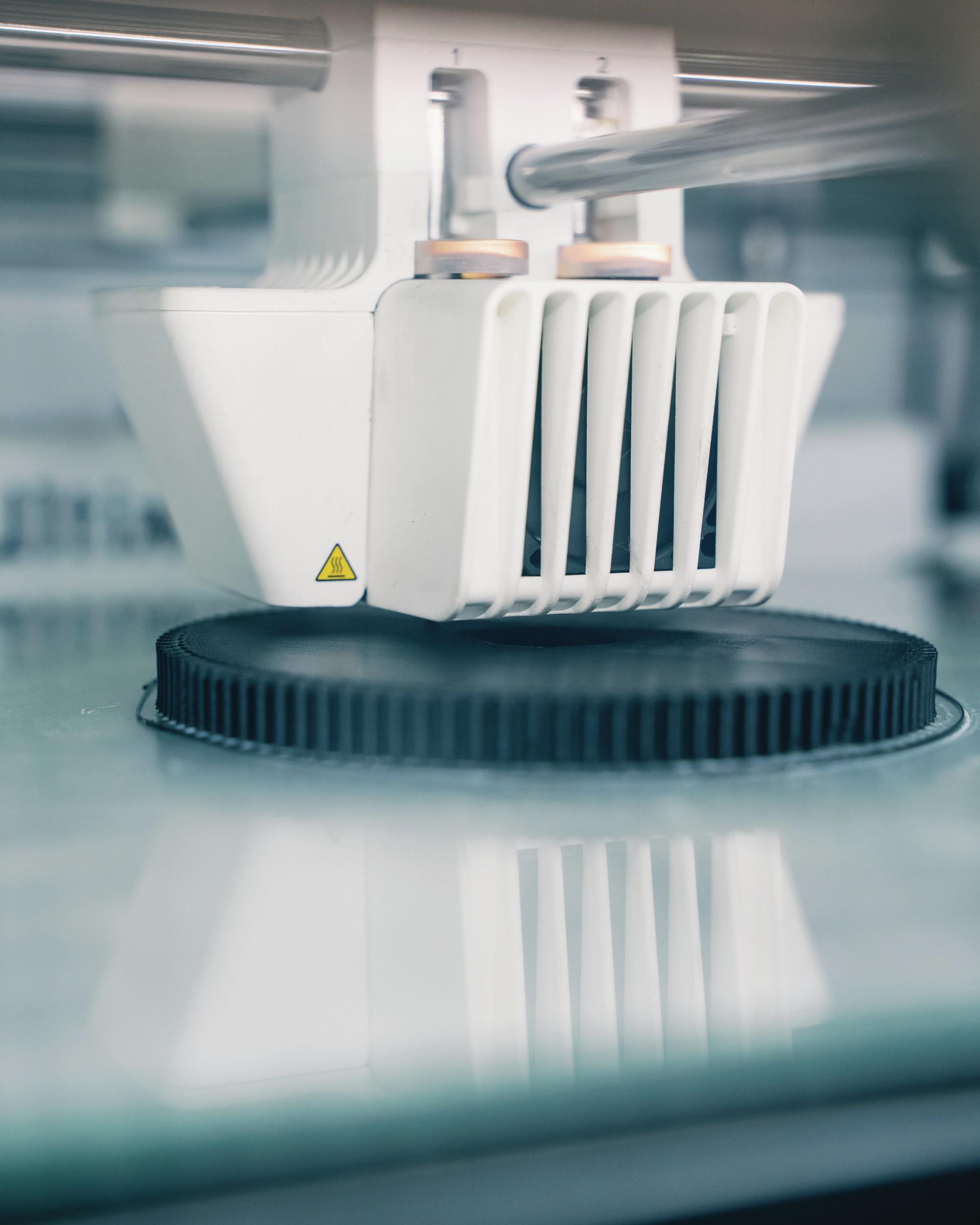

Encirc Beverages uses the 3D printing of machine parts to significantly reduce costs – and to protect the planet at the same time.

When it comes to industry innovation and sustainability Encirc looks to have every dimension covered.

Yes it has world-leading, ambitious plans to produce zero-emission glass by 2030, but the nuts and bolts of its sustainable business strategy goes across the board. This is especially so in its everexpanding beverages section, where 3D printing is significantly reducing costs, as well being an effective green solution.

Encirc Beverages has four 3D printers at its site in Bristol, and one at Elton in Cheshire, which provides closed-loop 3D printing. This method, known as additive manufacturing, is a process of making three-dimensional solid objects from a digital file. The creation of a 3D-printed object is achieved with additive processes, which create an object by laying down successive layers of material until it is completed. Each layer can be seen as a thinly sliced cross-section of that object. The process enables users to produce complex shapes using less material than traditional manufacturing methods.

3D printing of parts is now the norm at Encirc Beverages, with more than 700 parts in its operating machines.

Richard Lloyd, Encirc Beverages’ managing director, explains: “We’ve created closed-loop 3D printing. What I mean by that is we’ve now converted a waste stream of plastic backing, which our labels come on, into machine parts in our machines.

“It used to leave site with zero waste going to landfill, as it would be made into traffic cones. Now, it’s being extruded on site into filament that we are then using to 3D-print our spare parts with. As well as the environmental benefit of not having to ship parts across Europe, it is also more cost effective.”

This fits perfectly with Encirc’s comprehensive sustainability strategy headlined by its mission to decarbonise the production of glass by 2030.

SIGNIFICANT INVESTMENT

Following significant investment in Encirc’s printing machines in 2019, the company is now reaping handsome rewards throughout the business.

It enables stock holding to be reduced because of the ability to dynamically react to demand, with no shipping and ordering lead time. With the removal of shipping, the carbon footprint benefit is present with every part.

Previously, many of the parts would have been shipped from Europe at a much greater cost. Encirc’s ability to make the parts in house, gives it more flexibility and adaptability in terms of supply and demand.

What’s more, all the parts are stored in a database that can be shared between the company’s two sites, reflecting some of the positive collaboration envisaged when Encirc added The Park to its business portfolio last year.

(Image: Machine work: 3D printing)

When Encirc receives a new bottle format, it is able to create the design in house, without waiting on the supplier, thereby ensuring the product comes to market quicker, keeping Encirc Beverages ahead of the game.

Added benefits

3D printing also provides engineers with opportunities to learn new skills such as how to create CAD (computer-aided design) drawings, which increases engagement and role satisfaction.

Always looking to the future, Encirc Beverages allows some of its work mplacement students to be trained and gain experience in the use of 3D printing at a young age.

(Image: MD Richard Lloyd)

It is also built into their apprenticeship schemes, again protecting and investing in the labour market of the future. Lloyd said: “3D printing augments our engineering strategy. Using a rugby parlance, you can’t play a game only one way, you need a set of different techniques and angles to win the game, and that is the way we look at it. Old ways of manufacturing remain valid but 3D printing gives an innovative approach to our business.

“It is highly efficient, cost-effective, and sustainable, ticking many of the boxes upon which the business is built.”

Continuing the rugby analogy, it would be surpising if there was not a scrum of drinks companies wanting to take advantage of Encirc Beverages’ forwardthinking technology in the coming months and years.

Related news

Encirc celebrates its ‘superpower’ suppliers at new awards