Foss launches ‘game-changing’ analysis instrument for sparkling wine

Foss have launched OenoFoss 2, an instrument that allows winemakers to analyse their wines at the touch of a button in just over a minute – including, for the first time, sparkling wine.

The new model provides a faster and easier-to-use solution than the original OenoFoss which was launched in 2008, according to Søren Thiis Heide, program director of wine & beer in Foss’s R&D department, with user experience that is more “intuitive”.

“The old OenoFoss is also a fantastic instrument, but it uses a method that’s more dependent on the user and the skills of the user,” he explained. “With the new device, the winemaker can focus on making wine and the machine will provide the data. It gives you a super performance every time without the need for a trained operator.”

“It is also much easier to get started with it.”

No need to de-gas samples

The “game-changing gadget” can also cope with the complexities of sparkling wine as well as still wine and must, giving winemakers the information they need to make informed decisions on when to pick, control fermentation and when to bottle their wine, in just over a minute.

“It will be much easier for sparkling samples to be easily and rapidly analysed with the OenoFoss 2, so the cellar master can get on with the important business of making wine,” he said.

Previously, in order to test sparkling samples or must under fermentation, winemakers would have to de-gas the sample, however Heide said this is the first instrument in its field to allows testing without de-gassing.

It also includes a sucrose measurement that can be used when making a dosage in traditional method sparkling wine and self-cleans between tests.

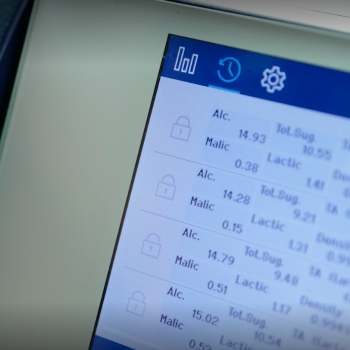

The winemaker takes a sample of wine or must, places it under the pipette and presses play, with results for the pre-set parameters – up to 34 different parameters, from ethanol, glucose and fructose to volatile acidity can be applied – appearing on screen in just over a minute.

Users have the flexibility to start with just a small selection of parameters and then add more as required in line with the demands of the winery.

Built on proven technology

The OenoFoss 2 uses Fourier Transform Infrared (FTIR) technology to scan the must or wine samples, using mathematical modelling and spectrum analysis to determine the different values. It has been calibrated using hundreds of thousands of wine and must sample references from around the world that have been collected since 1999, giving a breadth of the data that produce a highly accurate analysis, the company says.

Partner Content

“Getting within the ballpark of a good result isn’t difficult. Getting it very, very close to the true result is more difficult,” Heide explained. “And that’s where we’ve been looking very deeply at the data.”

“We’ve taken a big leap with this fantastic little machine and the legacy we’ve built into it. On the outside it looks similar to others on the market, but the mathematics built into it stands on the shoulders of all of the knowledge, experience and expertise that Foss has built up since 1999. Every single sample we’ve measured over the last 23 years has been input into this machine, which makes it a compelling proposition,” he said.

More time to be creative

Danish winemaker Jonas Tofterup MW, who is a partner at Bodegas Trenza in Spain, where he makes wine with his brother, David, said the speed of the analysis and its wide set of parameters made it hugely useful tool.

The duo currently produce more than 20 wines from different appellations across Spain and are still growing and exploring new regions and vinification methods. However Tofterup said that following their expansion in 2019, it had been challenging to keep up with quality control when relying on external laboratories – a time consuming and laborious process.

Being able to control this in-house rather than be dependent on external laboratories was a huge advantage, he said, both in terms of speed and cost, but also in terms of keeping the carbon footprint down and maintaining consistency.

“The equipment is seriously an advantage while doing the blending trials as it ensures we can have more consistency between different blends, and have better quality control,” he said.

“We can have the previous bottled wine and the diff components of the new bottling and compare the chemical parameters of the new blend against the previous wine to ensure high consistency between bottlings.”

“With this new instrument, we can be more precise and make key decisions quickly – and dedicate more time to be creative,” he said.

A video interview with the Tofterup brothers and more information about the OenoFoss 2 can be found here:

Related news

How analytical insights help craft fine Languedoc wine

Quality counts at Château Tanunda

FOSS: an uncompromising approach to analytical solutions for winemakers